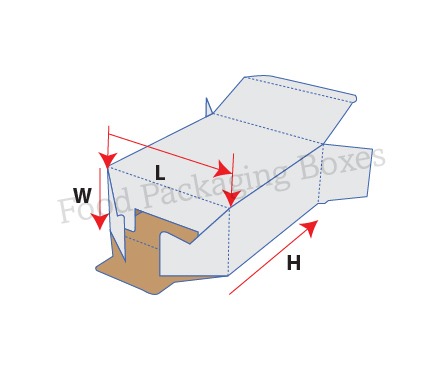

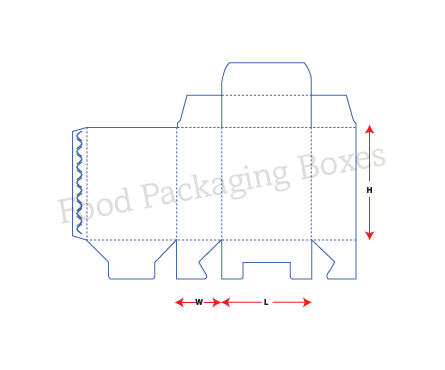

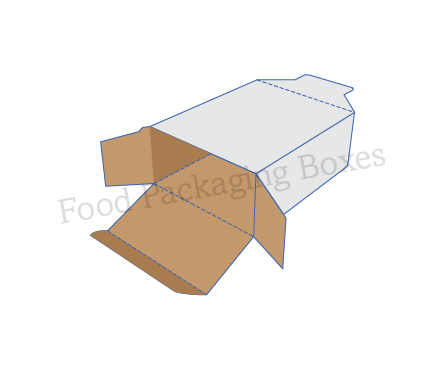

1-2-3- Bottom Boxes

1-2-3 bottom boxes are also referred to as snap lock boxes. Although these boxes may require a bit of time in assembly, they are however more secure than a tuck end box. The flaps that secure the bottom of the box have an interlocking mechanism in order to secure the contents. In order to achieve strength at the base of the box, an additional flap may be added. This will safeguard your contents from spilling out.

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 - 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 5-7 Business Days , Rush |

Once the three flaps are locked into position, 1-2-3 bottom boxes takes its original shape and is ready to be filled in with the contents. The strength of this box comes from the fact that the bottom is reinforced with three flaps interlocked. This sort of design can handle the weight of the product, for which it is made, easily. Just like a jigsaw puzzle, easy to assemble however, these boxes are designed on the principles of robustness and strength. In comparison with the tuck bottom boxes, these offer you a higher level of strength. However, they are a little less strong than an auto-locked bottom box. In regards to the cost of production, these boxes are the cheapest among the two other option we have mentioned. The interlocking mechanism provides full support to the extended top flap.